Building Envelope of Justice

A messy work site! Concrete poured for the basement through the basement living room window.

We insulated the foundation wall interior with 2" of EPS (Halo), and will use 7" of Roxul batt as interior insulation between the studs and held against the EPS lined foundation wall, which sits at an R40 rather than the R30 goal. The exterior foundation wall is protected from moisture by both a roll-on foundation coating and as well, a layer of dimple-wrap that wicks away water as it seeps in. The application of 2" of EPS on the interior of the foundation wall was chosen versus exterior due to an oversight during the foundation pour where a thermal bridge between one of our retaining walls and the foundation wall was created outside of the planned design, (we'll talk further on that in a later blog post!). The R value of the foundation wall falls at R40, better than an R30 goal.

The pony wall & exterior walls to the home are comprise of 10" of Roxul batt, formed in a 12" thick double-stud wall. The exterior 2x4 wall is insulated fully vertically, with another 3.5" of roxul installed overtop horizontally. A 2" air gap between this layer and the vapour-air barrier system is left with it's own insulating properties or R4, according to our energy modelling software. The basement pony wall does not have the air gap. Instead, its insulated fully with 5.5" of Roxul. On the interior framed 2x4 wall, we will be insulating it a third time with another 3.5" of Roxul, outside of the air/vapour barrier system after the electrical & plumbing have been completed. This is important as to not increase the likelihood of penetrations into the air barrier system to ensure we maintain our low air leakage goals as we move forward throughout construction. The final R value for exterior walls are R40.

Setting up the rebar for the slab pour overtop the EPS, vapour barrier & radon mitigation system.

The attic is insulated with roxul batt in between manufactured trusses, to get us up to around R80, over and above the R60 in the insulation rule mentioned previously. This is accomplished in part by raising the heel up to 20" in order to accommodate more insulation. We have yet to tackle this particular job, and theory and practice have not aligned perfectly in some cases, which is why we ended up with the air gap on the main floor. Not too big of an issue, as the final modelling calculations show that it made little difference. Theory and practice coming to a head has actually been kind of a running joke between myself and my partner. My energy modelling, building science literature, and hours of online learning have not necessarily aligned with the actual activity of construction, which he has plenty more experience in. But the experience so far has been invaluable and we've both learned so much.

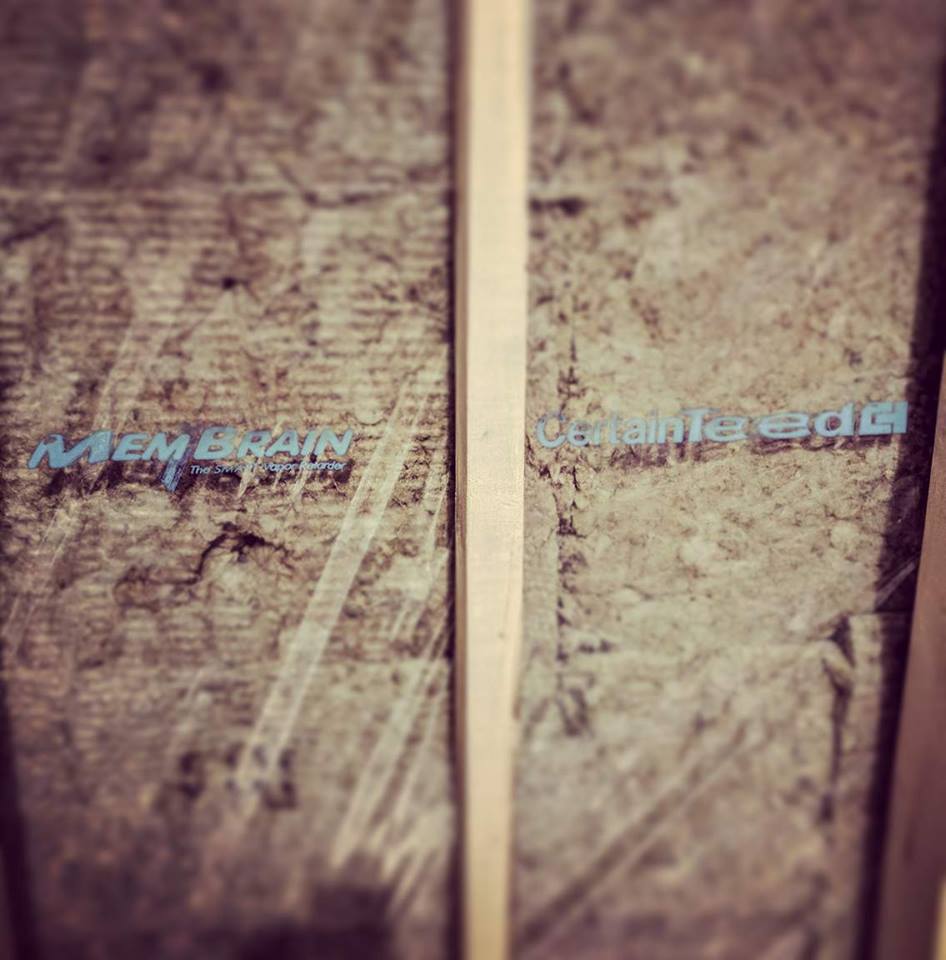

Air/Vapour barrier proteting 7" of Roxul. We have yet to insulate the interior utility cavity as our electrician & plumber have work still to do.

It's now mid-summer and we're all framed in, the concrete is now set and we're just awaiting our windows and exterior cladding. Now is a good time to talk about our building envelope strategy, now that the shell is up!

We tried to follow the 60-40-30-20 rule with regard to the insulation, but made some adjustments based on circumstances and new revelations. Some good, some bad. This rule basically states that, to build an extremely efficient home, you should aim for R60 in the ceiling, R40 in the above grade walls, R30 in the foundation walls and R20 in the slab. Here's what happened:

We'll start from the ground up. Our walk-out basement slab was protected by 2" of expanded polystyrene (EPS) around the frost wall on the exterior, and 4" of a combination of EPS & Extruded polystyrene. We would have went completely with EPS but our foundation guys threw up 2" of the XPS along the interior perimeter, which we added to. No sense in wasting it. The slab was poured over 3" of EPS (and our radon mitigation system), with all edges carefully insulated away from the foundation footings to reduce any thermal breaks in that location. The slab itself sits at R12, not R20 as initially planned. The reason why we couldn't fit the additional 3 inches of EPS we intended on installing was due to a few factors, which we will touch on in a later blog post. However, after considering the other insulation values of the rest of the home's components, this reduction in R value for the slab made little difference in the overall performance of the house.

Drainage wrap along the exterior of the foundation wall to help shed water.

In the end, we are sitting at 80-40-40-10. Our final energy modelling numbers have been updated to reflect a great reduction in energy usage due to recent decisions and choosing high performance windows. More to come on that in a later blog.

The air/vapour barrier is comprised of 65% poly under slab, around the edges of the wall systems, and at the ceiling, complimented by a smart vapour/air barrier Membrain by Certainteed. This barrier responds to the moisture in the environment and allows the walls to breath much better than poly. This is especially important for thick walls, and in basements where moisture may accumulate. We've been using Siga Rissan tape, a favourite among Passive House builders as our vapour/air barrier sealer. Sign Rissan is what I like to call the bandaid of Passive Houses. We patched so many holes that were created by inexperience and accidents with this tape and I am confident that the leaks were sealed. I am also confident we will use quite a bit more as the project moves forward. This tape is sticky as hell and once you use it, you'll never go back to red or even blue tuck tape. It's so easy to work with, and waste is spared by the tape coming with a backing, so you can easily peal off what you need and save the rest for later. Which is good, because it's kind of expensive. Shout out to Tom at Small Planet Supply for ordering us some in on short notice!

The Thomas House Project mascot isn't looking too enthused. Her ball is holding the rebar up!

Just a note on air-tightness. We have yet to do our first blower-door test, which will happen shortly. One of the benefits of having an airtight house over and above the reduction of heat loss, is the fact that your home will have very few critters in it! There will be no opportunities for bugs to get into the building envelop in this passive house!

We have most of the weather barrier installed to the exterior of the house, including the roof, and are waiting on materials to complete the exterior portions of the building envelope. The roofing material will be Euroshake by Euroshield, which is a recycled rubber shake. This is an extremely hardy roofing material that will be able to withstand the severe weather conditions, such as large hail, that Albertan's are used to. Our exterior walls will be clad in smooth Hardie Panel, and Lux aluminum panels added for architectural detail, which is made locally, here in Alberta!

Our windows are currently on a ship from Austria's Internorm! This is one of the most exciting parts of our build and we recently had a chance to see them in person, in their showroom in Montreal. Not only are they beautiful, crafted carefully with forethought and with quality materials, but they are innovative in design as well. Each operable window opens inward in a horizontal fashion, but as well inward in a vertical fashion from the bottom. These windows are high performance, triple pane, low-e with solar heat gain coefficients (SHGC) differing by orientation and thermal heat gain need. The final spec's for the windows rest at approximately 0.5 W/m2K (R2); Uf of 0.92 and Ug of 0.5/0.6, and the entrance door at 0.75 W/m2k (RSI .13 & (R7.7). Remember, the U value of passive house windows should be no more than .08 W/m2k, which ours are under. Click the button below for some information on Passive House windows, some light, leisurely reading!

Panorama of the interior before the roof went up. You can see the interior walls have been stood up with the air/vapour barrier installed and 2 layers of Roxul on the exterior side.